Daniel Grunenberg

CEO & Founder

SpeedPox allows to reduce curing times from hours to minutes or even seconds. Full conversion is achieved - no post processing needed!

SpeedPox epoxies are premixed one-component systems and ready-to-use. Compared to regular systems our customers will have no more stress with the processing after mixing.

When compared to large autoclaves, SpeedPox helps to reduce the energy consumption by >99%.

SpeedPox GmbH was founded by Daniel Grunenberg in 2020. It is an Austrian based technology start-up that aims to revolutionize the manufacture and use of epoxy resin systems.

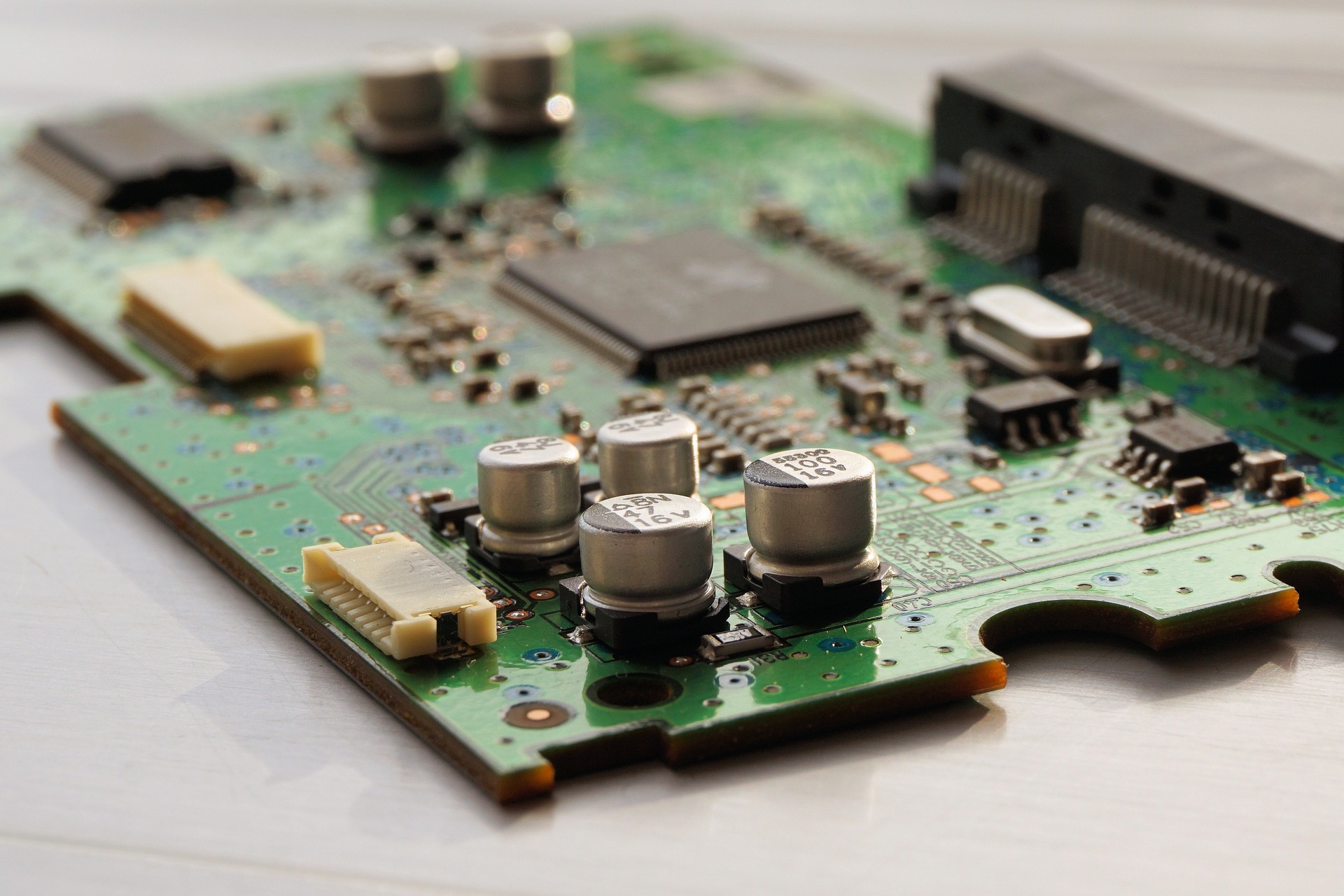

SpeedPox offers an innovative and extremely fast curing epoxy resin. Its epoxy resins are one-component systems that can be stored for a longer period of time. The patented self-curing process can be started individually with the help of UV light or another heat source. Once started, the process continues and nothing stands in the way of even curing. The resin can be used in a wide variety of industries, from electronics to automotive, construction and the maritime industry. SpeedPox is part of the TU Wien i²c incubator program and is funded by AWS PreSeed and AWS Seed.

CEO & Founder

COO & Co-Founder

CTO & Co-Founder

CFO & Co-Founder

The unique turn dark technology of SpeedPox Glob Top enables rapid UV curing of black epoxy resins within seconds at room temperature.

Preliminary studies with SpeedPox technology have shown that our production cycles can be reduced to a few seconds instead of 20 minutes.

Through SpeedPox's technology it is now possible to cure epoxy resin underwater which opens completely new business opportunities.

Holz-Steiner-Straße 6, Objekt 4a, 2201 Seyring, Austria

+43 2246 50701

office@speedpox.com

Mon - Fri, 8:00-18:00